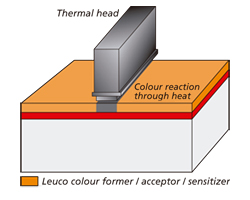

In thermal printing a colour image is created through the direct transfer of heat (thermal energy) to colour-reagents in the thermal-sensitive paper. The degree to which these colour-reagents (leuco colour former, acceptor) react is precisely controlled by special melting point regulators (sensitizer). In this way, various monochrome shades can be created depending on the amount of energy transferred.

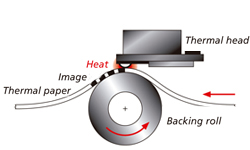

The thermal head in the thermal printer transfers the heat to the thermal paper. A thermal head consists of a multitude of miniature heating elements distributed along its printing width. This is why a thermal printer has considerably fewer moving parts than any other printer. Each of these tiny heating elements is electronically controlled to deliver the right amount of energy at the right time. In this way, the individual colour points are created which together form the final image – text, graphs, bar codes, etc. A backing roll ensures that the thermal paper stays in constant contact with the thermal head.

The thermal head and the paper are thus the main elements of the thermal printing process.

Thermal printers have the following characteristics:

- very high reliability

- small, compact printing unit

- easy handling in applications

- few moving parts and no additional consumables (e.g. toner or inks like in other printing processes)

- low maintenance costs

- low noise due to the "non-impact" printing process

- fast (up to 16 inches/sec or 400 mm/sec)

- high image resolution (up to 400 dpi)

- high functionality even under extreme environmental conditions